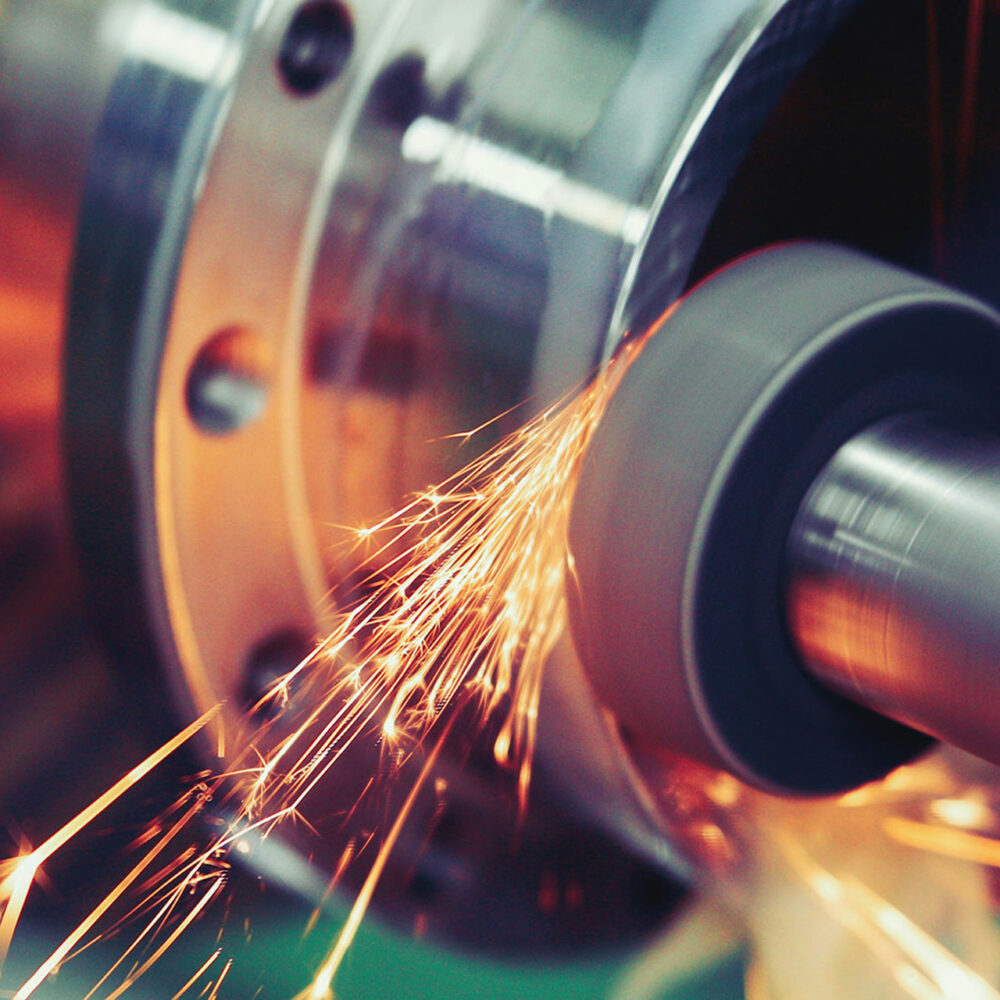

CR Strips / Coils

On line stringent quality checks ensure the tolerances and dimension for sophisticated applications

CR production plant consists of two 4 HI and one 6 HI cold rolling mills along with bell furnaces, Skin Pass, Slitting, cut to length and testing facilities.

Products Range

- CRCA strips with low carbon

- Medium carbon steel

- High strength low alloy steel

- Semi processed unalloyed electrical

- Hot rolled oiled & picketed steel